EVM

EVM's are special-purpose rubbers serving as a good alternative to many conventional rubbers when superior heat and weathering resistance is needed. EVM is a vulcanized copolymer of ethylene and vinyl acetate.

Levapren® consists of methylene units forming a saturated polymer backbone with pendant acetate groups. These rubber-like copolymers are designated ethylene-vinyl acetate copolymer (EVM). Our ethylene-vinyl acetate copolymers are used as synthetic rubbers, or as modifiers in thermoplastics, specifically PVC.

The benefits of Levapren® include:

- Radical solution polymerization with good physical properties

- Halogen-free (no formation of HCI in case of fire)

- No points of attack for ozone or UV light

- Excellent weather and heat resistance (up to 175 °C)

- Balanced oil resistance, low temperature properties and flame retardance through proper choice of vinyl acetate content

ARLANXEO offers its customers a comprehensive range of synthetic rubber products, with specialties such as Levapren®. Wherever conventional polymers reach their limits, Levapren®, a polymer with very good heat and weathering resistance, is a suitable alternative.

Levapren® is produced by copolymerization of ethylene and vinyl acetate. In principle Levapren® consists of methylene units forming a saturated polymer backbone with pendant acetate groups. These rubber-like copolymers are designated ethylene-vinyl acetate copolymer (EVM). The presence of a fully saturated main chain already indicates that Levapren® is a particularly stable polymer. Degradation generally only occurs at very high temperatures and even then very slowly.

The general property profile of the copolymers produced from ethylene and vinyl acetate is determined in the first instance by the ratio of the two components. The reactivity of the two monomers is almost similar so that they are statistically distributed throughout the copolymer chain, which is perfect for rubber applications.

Properties of Levapren® vulcanizates

- Hot air and oil resistance: If properly compounded, Levapren® vulcanizates display excellent aging resistance and also continue to function over extended periods of stress at elevated temperatures. The heat resistance of Levapren® vulcanizates is considerably better compared to most other common elastomers.

- Halogen free and flame retardant non corrosive (FRNC): Levapren® is the material of choice wherever flame retardancy has to be achieved. It features the advantages of being halogen free and of burning with non-corrosive emissions. Flame retardancy is achieved by adding high amounts of specialized fillers, such as aluminium hydroxide or magnesium hydroxide. The flame-retardant properties of Levapren® vulcanizates are not only affected by the amount and kind of filler in the compound, but also by the vinyl acetate content of the EVM grade used. The higher the content of the vinyl acetate, the higher is the limiting oxygen index (LOI) of the resulting material and therefore the lower the flammability.

- Weathering, UV and ozone resistance: UV radiation, ozone, rain and industrial waste gases can significantly deteriorate the properties of elastomers. The effects are described according to their appearance as ozone cracking, crazing (non-oriented tear cracking), chalking, softening or hardening. Vulcanizates with light-colored fillers in particular are sensitive to these influences.

Levapren® vulcanizates show none of these effects after outdoor weathering tests conducted over a 2-year period. The samples were still useable at the end of the trial.

- Mechanical and dynamic mechanical properties: The high VA content Levapren® grades (Levapren® 800 and Levapren® 900) provide high damping at room temperature whereas the low VA content grades (Levapren® 400 and Levapren® 500) show an extremely elastic behavior. Different Levapren® grades can be blended, thus delivering an elegant way to produce materials with tailor-made dynamic mechanical properties.

Main applications

- Seals: Due to its long-term heat stability and its good resistance to automotive fluids, Levapren® is used in seals, e. g., for rocker head covers.

- Hoses: Levapren® is used as base material for flame-retardant and chlorine-free hose covers like in fuel hoses

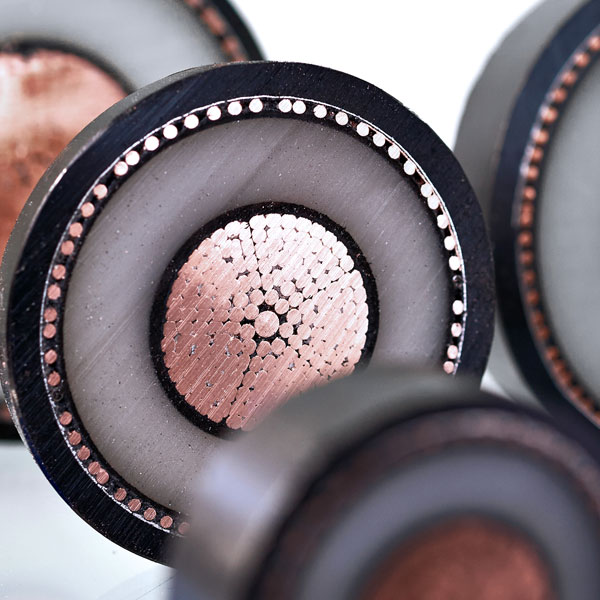

- Cables: Due to the high flame retardancy and the heat and chemical resistance of FRNC Levapren® vulcanizates, cables are one of the key applications of Levapren®. Many cables in buildings, ships and mass transit or rolling stock are made of FRNC Levapren® compounds.

- Floorings: Floorings based on Levapren® give benefits like good resistance to wear, abrasion, ozone, weathering and they offer outstanding color stability.

- Sensor cables: Due to its unique polymerization process, the molecular weight distribution of Levapren® is in particular wide. The gel-free product has a positive effect on the processability of the material and the quality of the end product such as the sensor cables. Gel particles would impact the function of the cables and therefore cause safety problems.

- Translucent articles: Flexibility in design without compromising in properties is one of the common challenges in the industry. Levapren® enables designers to create translucent articles with very good weather and UV resistance which in most cases can only be achieved with carbon-black-filled rubber articles.

- Foams: Typical applications are in ships, railways and buses.

EVM's are special-purpose rubbers serving as a good alternative to many conventional rubbers when superior heat and weathering resistance is needed. EVM is a vulcanized copolymer of ethylene and vinyl acetate.

Formed by copolymerization of ethylene and vinyl acetate, Levamelt® is a versatile and flexible polymer for durable adhesives and films.

Wires and cable in the automotive and industrial sectors must safely operate under often extreme heat conditions. Protective rubber compounds must meet stringent standards.