Energy, Oil & Gas

The demands in the oil exploration industry are extremely high. From explosive decompression to elevated mechanical stresses, elastomer solutions must meet the challenge.

Hidden multitalented parts

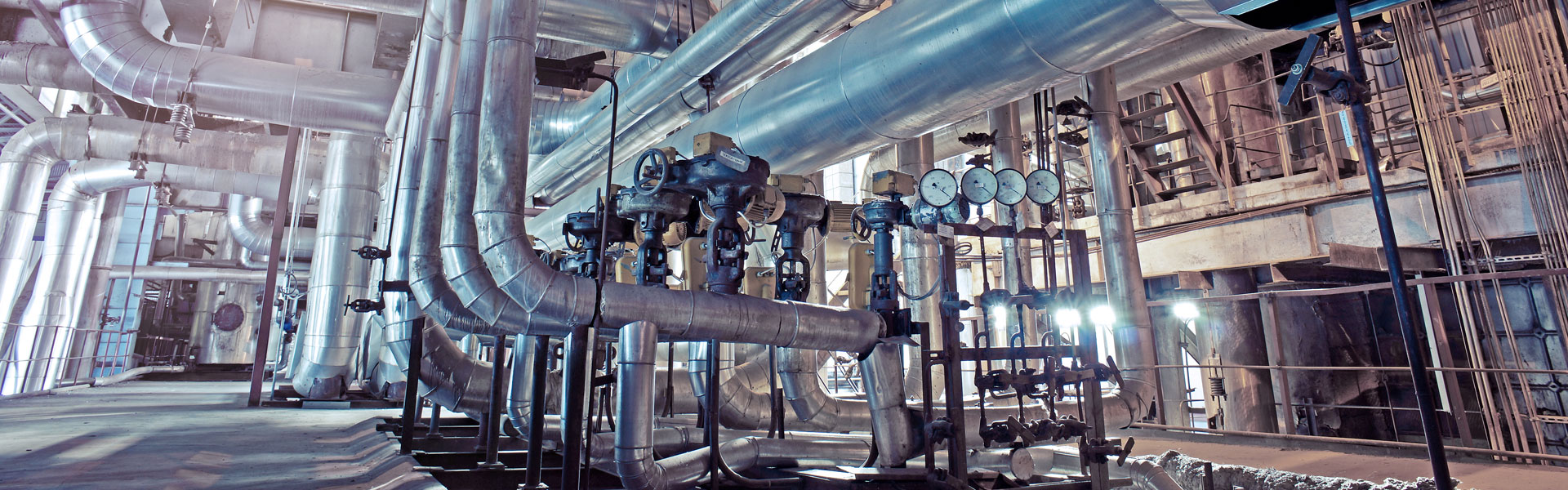

In industry, large equipment and machines are in continuous use and enormous forces are in play. And wherever something moves or is moved, synthetic rubbers are at work – with different properties for every conceivable application.

Oil and gas production is particularly extreme. Many rubber seals can be found on drilling systems, including on rinsing pumps, drilling heads, and hose lines. This is where Therban® comes in. The hydrogenated acrylonitrile-butadiene rubber (HNBR) is insensitive to oil, gas, heat, and aggressive flushing fluids. And it can withstand the toughest vibrations – perfect for dampers in ship couplings, wind turbines, and railways, for example.

Special rubber for all-purpose hoses

Seals with our HNBR Therban® also withstand high pressure and strong friction in pumps. For example in rotary piston, eccentric screw, and concrete pumps. And with a special Therban® grade, rubber seals can be integrated into plastic oil pans efficiently in just one production step.

In industrial settings, hoses also have to keep a perfect seal, often under the toughest conditions. With a cover made of Baypren® chloroprene rubber, all-purpose hoses can withstand high loads as well as oil, ozone, cold, and heat. And the NBR Krynac® is compliant with highest standards and, therefore, particularly suitable for hoses for transporting food.

Hard workers underground and above ground

When transporting oil, fuel, gas, or electricity, there is an increased risk of fire – particularly dangerous in large production plants, wind turbines, and submarines. These substances therefore often flow through lines with Levapren. The halogen-free ethylene vinyl acetate rubber (EVM) compounded with suitable fillers is highly flame-retardant while not releasing toxic smoke gases.

Levapren and other abrasion-resistant synthetic rubbers also perform extremely hard work in rollers, conveyor belts, and drive belts – whether transporting freight containers, parcels, or luggage or in steel processing, coal mining, or the paper industry.

Another EVM is Levamelt®: this rubbery adhesive and modifier for thermoplastics allows both car body panels to be firmly joined together and self-adhesive notepads to be easily detached from the substrate. And adhesives with Baypren® can be processed particularly quickly, are weather- and oil-resistant, and elastic. Butyl rubber X_Butyl® is perfect for transparent adhesive tapes, seals for double glazing windows, and high-quality hot-melt pressure-sensitive adhesives – as well as for safe work wear such as face masks, breathing apparatuses, and protective suits.

The broad portfolio of Keltan® EPDM grades is well equipped to meet the processing and physical properties of the (molded) rubber goods industry. Keltan® grades are suited for use in various industrial and machinery applications for example in conveyor, drive and transmission belts, in industrial hoses, printing and paper rollers as well as in gaskets, bladders and swell packers. The portfolio includes grades with high-molecular weight as well as oil-extended polymers for high strength and low hardness applications. Moreover, Keltan® grades with low unsaturation are available, contributing to an optimal heat aging performance.

The demands in the oil exploration industry are extremely high. From explosive decompression to elevated mechanical stresses, elastomer solutions must meet the challenge.

Wires and cable in the automotive and industrial sectors must safely operate under often extreme heat conditions. Protective rubber compounds must meet stringent standards.

Oil additives play a vital role in improving the performance and longevity of modern combustion engines. ARLANXEO's Keltan® range of polymers helps regulate the all-important viscosity index.