HNBR

HNBR rubber is a hydrogenated NBR specially designed for demanding applications requiring excellent durability in aggressive environments over a wide temperature range from -40 to 165°C.

Therban® is a partially or completely hydrogenated nitrile butadiene rubber. While all HNBR products exhibit certain characteristics such as strength, heat resistance, and oil resistance superior to standard NBR and other polymers, only Therban® offers a selection of grades that will perform well across a range of the most extreme environments.

Designed for demanding applications requiring exceptional durability in aggressive environments, Therban® offers the following benefits:

- High resistance to oil and grease

- Ability to function at temperatures from - 40 °C to 165 °C

- Superior performance in aggressive fluids such as power steering fluids, automatic transmission fluids, engine oils, diesel and brake fluids

- A unique range of thermally stable grades with both partial and full saturation, ranging from 17 % ACN to 44 % ACN

- Excellent abrasion resistance

- Excellent ozone resistance for fully saturated grades. For partially saturated grades only if proper compounded.

Therban® is already indispensable in automotive systems, oil exploration, mechanical engineering and aerospace. Our research team is focused on extending this advantage.

Seals

Therban® superior line of fully saturated grades with high heat resistance is suited to seal applications in automotive systems and heavy equipment. Our fully saturated LT grade Therban® LT 2007 provides an excellent combination of high and low-temperature performance, ozone and oil resistance and is ideal for long-term performance in off-the-road vehicle and automotive seals which come into contact with oil and grease.

Use Therban® for:

- wheel bearing seals

- shock absorber seals

- camshaft seals

- power steering assembly seals

- O-rings

- water pump seals

- gearbox shaft seals

- air conditioning system seals

- fuel system seals for diesel and RME coolant seals

Oil well specialties

High ACN saturated grades are best for low swell and explosive decompression resistance. This also applies to fuel and refrigerant applications. No other supplier offers a line of fully saturated HNBR grades that equals Therban® for performance.

Use Therban® for:

- blow-out preventers

- packers

- drill-pipe protectors

- pump stators

- drill bit seals

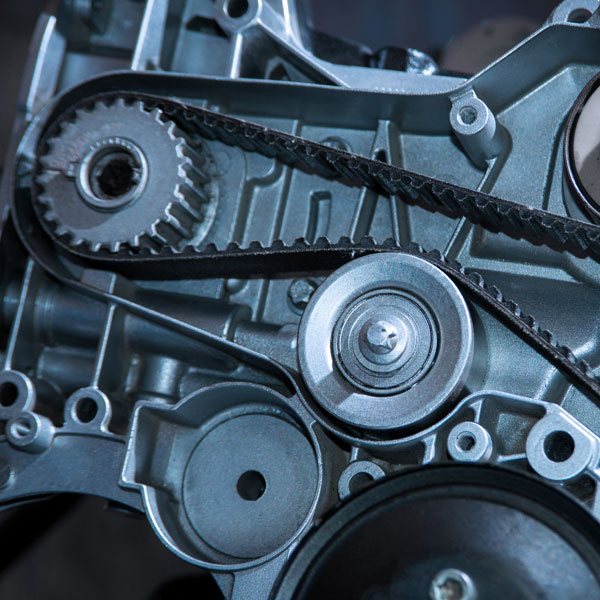

Belts, hoses, mountings

Therban® LT grades are especially suitable for applications where cold flex cracking is a problem, as in snowmobile belts. Therban® partially hydrogenated grades are the right choice in these dynamic applications.

Use Therban® for:

- air conditioning hoses

- timing belts

- engine mountings

- oil-cooler hoses

- torsional vibration dampeners

- boots and bellows

- chain tensioning devices

- fuel hoses

- overflow caps

- power steering hoses

- ship couplings

- high-pressure hydraulic hoses

- applications with a high dynamic load

Wire and cable

Medium-high ACN fully saturated grades are ideal for wire and cable applications.

Use Therban® for:

- protective components for electrical systems

- protective jackets for electrical cables and wires

- blends with EVM/Al(OH)3 for FRNC cable jackets with excellent flame-retardant properties and excellent low temperature properties

Roll Coverings

Therban® AT grades are especially suited to high hardness roll applications; they combine high modulus and good dynamic properties with low compound viscosity and high abrasion resistance. All partially saturated Therban® grades from ARLANXEO are ideal for these dynamic applications.

Use Therban® for:

- metal-working rolls

- paper industry rolls

- printing rolls

- elastomer components for looms

- textile rolls

- rolls for transport of containers in aircraft

Do you need further information about our products and their applications or regulatory declarations? You can also use the contact form for any questions about career opportunities at ARLANXEO, media enquiries and other topics.

Get in touchHNBR rubber is a hydrogenated NBR specially designed for demanding applications requiring excellent durability in aggressive environments over a wide temperature range from -40 to 165°C.

Nitrile-butadiene rubber (NBR) is a copolymer made from butadiene and acrylonitrile. NBR is essential for technical rubber products that need to be resistant to mineral oils, service fluids, and greases in automotive applications and machinery.

Be it in tires, performance parts for cooling systems, or brake pads, we are helping to make sure cars meet the sustainability requirements of tomorrow.